Deep Drawn Metal Forming

What is deep drawn?

Deep drawing is a form of metal stamping where the depth of the draw is typically greater than its diameter. In practice, it is possible to produce long, narrow, cylindrical parts with a length that is significantly greater than the outside diameter of the part.

Whether It’s A New Or Existing Product,

Your Final Design will perform To The Highest Standards

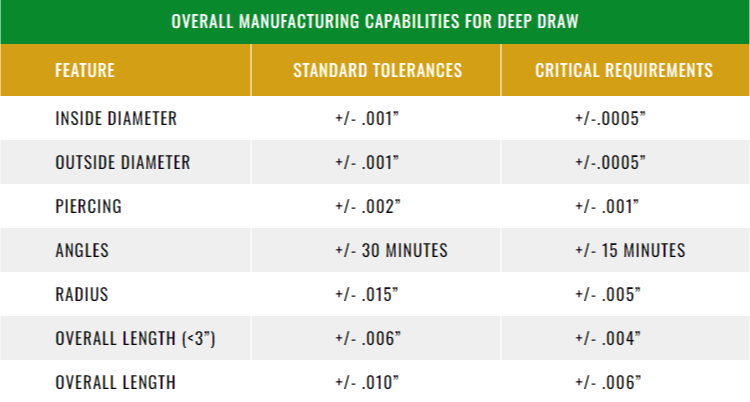

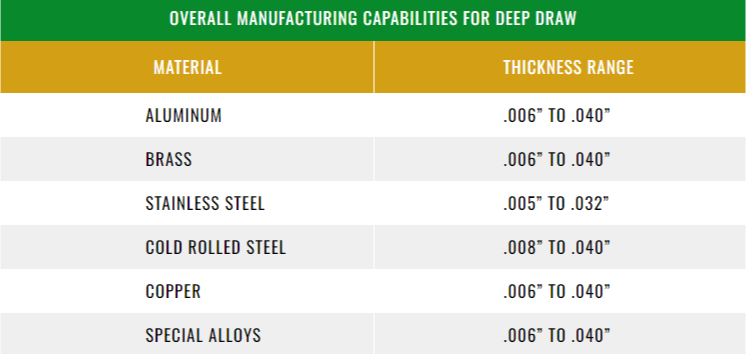

Our Bliss, Waterbury and Ferracute presses enable us to create high quality, tight tolerance parts of long lengths and small diameters from: aluminum, brass, copper, stainless steel, cold roll steel, tin plate and various precious metal alloys

* We are also able to meet other requirements outside of the standard.

Accurate Forming’s precision processes can achieve diameter to drawn height ratios of 8:1 from stainless steel and 20:1 from

other alloys with a wall thickness range from 0.005” to 0.040”.

What are the benefits?

One of the main benefits of deep drawn metal forming is low cost of production/operation per part because of:

- High volume of production due to high capacity and high speed of the press.

- The finish doesn’t require further processing, and secondary operations such as beading, notching, chamfering and piercing can be performed within the deep draw tooling.

Custom Metal Finishing

Nickel and chrome plating not only enhance the aesthetic appeal of metals but also significantly increase their durability and resistance to corrosion. This makes them popular choices for a wide range of applications, from automotive parts to household appliances.

Powder coating provides a durable and environmentally friendly finish for metals, offering superior resistance against corrosion, scratches, and fading. Its versatility allows for a wide range of color options and finishes, catering to diverse aesthetic preferences and industrial needs.

Electrostatic applied lacquer utilizes an electric charge to adhere the paint to the metal surface efficiently and evenly. This method ensures a smooth, high-quality finish with no drips or runs.

Metal polishing enhances the surface quality of metals, producing a smooth, reflective finish. It removes imperfections and prepares the metal for further finishing or application.

We offer other finishing services including, but not limited to:

- Heat Treating

- Anodizing

- Burnishing

- Four Color Lithography

- Surface Detailing

Built for your Industry

Medical

Automotive

Appliances

Military & Law Enforcement

Industrial

Writing Instruments

Markers

Electronics

HVAC

Our Process

Accurate Forming’s end-to-end process provides your products with metal stamping and metal finishing supported with project management to meet all of your application needs.

Our Differences

The Accurate Forming team is a group of skilled engineers with years of experience in metal stamping. We’ll support you from start to finish in creating your product. Learn more about what sets us apart.

Get a Custom Quote Today!

Looking for precision metalworking services tailored to your specific needs? Let’s bring your vision to life! Contact us to receive a personalized quote. Our team is ready to provide you with expert advice and a detailed estimate for your project. Simply fill out our quick form, and we’ll get back to you with a competitive quote that matches your requirements.