Resource Library

Blogs & Articles

With a streamlined process, Accurate Forming was able to increase production volume and reduce costs successfully allowing the company to

Finding the best deep drawn metal supplier to make your products can be a difficult and time-consuming task.

When deciding how to get parts or products made for your company you need to make sure you’re picking the

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

Given the on going dynamics of a fluid marketplace, it can be a challenge when seeking suppliers as to utilize

There are many manufacturers available on the market and this can present a challenge when you need the right manufacturer

Being much more than a simple tube filled with ink, a writing instrument takes a quality design to make it

All manufacturers face challenges. Some of the most common being bottlenecks or limitations to their processes which force higher costs

It has long been understood that pressing or stamping is an economical method for manufacturing complex parts. Although there’s a

Metal forming is one of the most important manufacturing processes available for the production of an expansive array of parts

The manufacture of equipment, machinery and consumer goods involves numerous steps that culminate in final assembly. Some operations are performed

When considering manufacturing, material and production are key elements to determining the overall cost benefits of the various processes. While

The deep drawn manufacture of components is unique in its overall adaptability. Few people who look at the barrel of

The traditional approach to the manufacturing and assembling of small components and products is a combination of fabrication and machining

Deep Drawing manufacturing processes offers significant cost efficiency over other manufacturing methodologies. This is particularly true in cases where specific

Although the initial investment in deep drawn tooling is more costly, the manufacturing costs of deep drawn components are significantly

Deep drawn manufacturing of small cylindrical components offers numerous advantages over other manufacturing methods and usually results in lower costs,

While there are many different manufacturing processes available, only the deep drawing process confers both technical and commercial benefits that

Unlike other manufacturing and industrial processes, deep drawing offers several technical benefits that make deep drawn parts highly sought after

A manufacturing process comprises a series of operations for the manufacture of individual components that are then assembled to produce

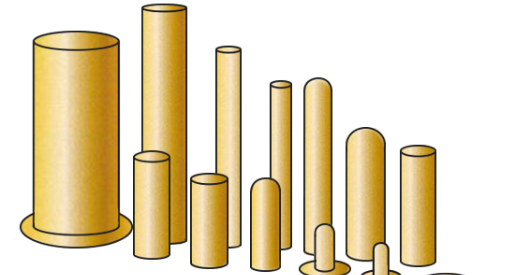

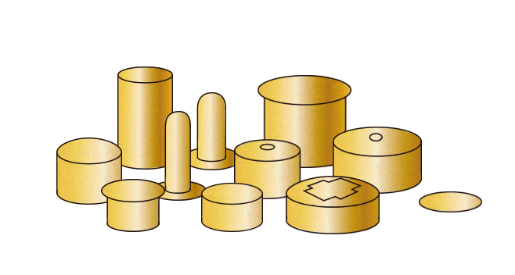

Many devices used by industry, law enforcement and other agencies have a cylindrical shape. Typical examples include pencil torches, writing

After years of outsourcing manufacturing overseas on the premise that it would reduce costs, more and more Americans are beginning

Despite global upheavals, the United Nations Industrial Development Organization (UNIDO) reports the manufacturing industry around the world is growing at

To some extent answering the question as to which manufacturing process is the most reliable is like answering a question

Although the trend to offshore manufacturing jobs appears to have peaked, many American companies continue to move production from the

With the demand for cheaper products, many American manufacturers assemble or purchase manufactured goods overseas. But this comes at a

Amid the recent economic turmoil in Asia, specifically China, you might be wondering: what’s destabilizing labor overseas? The answer is

As many buyers have discovered, local purchasing is simpler and altogether more convenient than offshore sourcing. And with the steady

When looking for a supplier or manufacturer, companies want value and usually that value is determined by cost. Honestly, getting

Deep drawing processes are used to manufacture high quality parts at a lower cost than comparative processes. Deep drawing requires

Just recently the Shanghai Index started crashing leaving everyone asking “why?” Did it have to do with the price of

While foreign manufacturing offers the prospect of inexpensive parts and labor, the incidental costs that occur can make outsourcing to

American manufacturing is slowly emerging from the industrial decline that occurred in the 1990s and the 2000s when there was

Manufacturers continually face pressures to reduce costs to maintain profitability, and new suppliers entering the market increase competition and put

Monetary consideration when it comes to manufacturing poor quality products, while challenging, is not the benchmark for negative results and

Although the days when your buyers routinely looked offshore to purchase deep drawn components are fading, it’s essential that U.S.

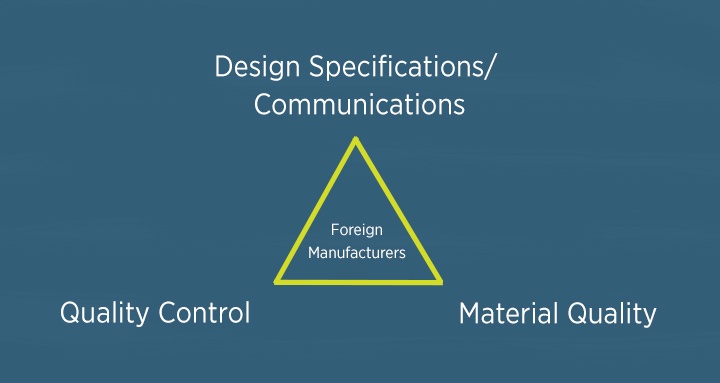

When engaging with, and outsourcing to a foreign manufacturer, it is important to recognize that there are hidden costs in

While outsourcing to a foreign manufacturer might seem like a cost effective solution, going with a foreign supplier is not

When looking for a supplier for deep drawn components for your business, getting the right supplier or manufacturer is vital

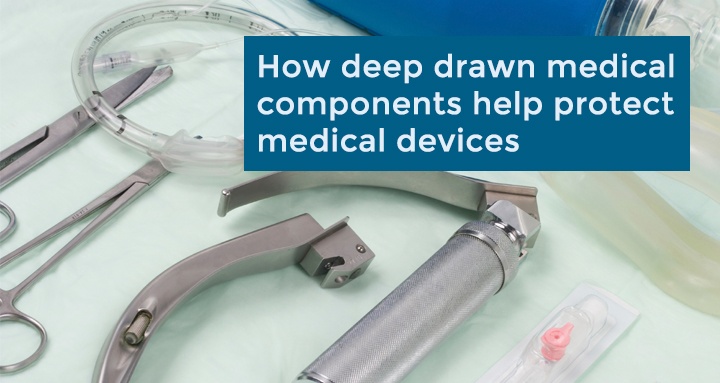

Medical equipment is manufactured to the highest standards to ensure components exhibit the right combination of characteristics such as adequate

When it comes to medical devices and their components, due to the importance and criticality of each individual part, the

The manufacture of components for medical equipment is governed by the FDA. Medical equipment manufacturers must be registered and the

INTRODUCTION: The list post is one of the most popular and readable blog formats on the web. It is composed

One vital and critical area of the medical arena, especially in facilities, is infection control. Simply put, infection control is

At one time there was a belief that society would become paperless, but despite the widespread uses of tablets, laptops

A major factor for successful and efficient manufacturing of quality writing instruments is the supply of high-quality components that are

The ubiquitous pen has a long and storied history. From the first uses of a feather to scribe upon papyrus

The art of communicating through written form has brought the global human community together, and at times tore us apart.

Over the decades, medical instruments have evolved from crudely crafted and rustic devices into what many might feel are modern

When it comes to the medical industry, there are few places more intimidating than the dentist’s office. No matter what

To most people, the manufacturing industry and the medical field have virtually nothing in common. Just the word manufacturing brings

The process of deep drawing metals to create products is rapidly becoming one of the premier methods of manufacturing. The

If you have ever taken a trip to a historical museum, one of the exhibits that you have no doubt

It might not seem evident, but safety is a prime concern for members of the military. The men and women

There are many things around us all that we overlook, or take for granted. Most are small, seemingly unimportant details

The deadline looms closer. You have a reputable deep draw supplier manufacturing a critical part, but to be honest you

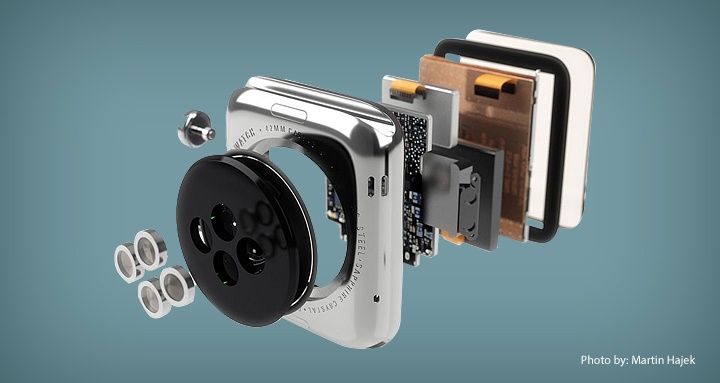

The sophisticated manufacturing process used in the creation of the new Apple watch combines technology with engineering to produce a

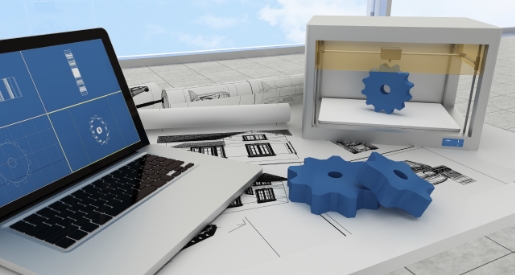

The rapid prototype process, and the 3D printing that makes it possible to create physical objects from computerized data, is

The deep draw process is very well known for manufacturing products such as caps, ferrules, and other small items, but

The deep draw forming process is rapidly gaining popularity as one of the most cost effective and sought after methods

In any project, communication is the key. Without a strong communication plan, some of the most pertinent information can get

Change is inevitable. Even the best, most long term contracts are bound to come to an end at some point.

By design, deep drawn cans have many benefits over other manufacturing methods. They are seamless, concentric, and the speed of

Every manufacturer knows that to stay competitive in the market, cost is king. The ability to reduce cost while maintaining

Choices…choices. As people, much of our lives revolve around the choices we make. Some are simple and we make them

They say that bigger is better. In the manufacturing world however, sometimes it is the smaller products that take the

Like any other product or service, there are always choices when selecting a deep drawn supplier. And like any other

They say that the devil is in the details. Anyone who has managed an engineering or manufacturing project will certainly

Sometimes, the best way to know the future is to understand the past.

We all want the most value for our money. It’s human nature. Add to that a few demanding stakeholders and

Although the finished product might look simple, and no doubt the experts make it look easy, the deep drawn process

In the manufacturing world, there are always many different paths to the same outcome. Several machining processes are capable of

It’s all about the numbers. Numbers, and the meanings behind them, drive the vast majority of the decisions we all

By definition, any collection of activities that function towards the same goal can be called a project. These projects can

The world was a different place fifty years ago. There were no computers, no cell phones, and if someone asked

Certifications. We all know they are important factors that can alter our perception of virtually any company, organization, or even

We always question what we may not understand. It’s human nature. As people, we rely on each other for information

The Occupational Safety and Health act of 1970 (OSH Act) states that, “all employers shall provide a work environment that

When it comes to choosing the right deep drawn metal stamping company for your next project, one of the most

By definition, value added operations include additional processes or features that enhance the product and meet specific customer needs. As

Times have changed. Technology has brought the world closer together and made it easier than ever to share information over

Scrap. Just the word brings to mind wasted time, energy, and most of all money. Modern machining methods have become

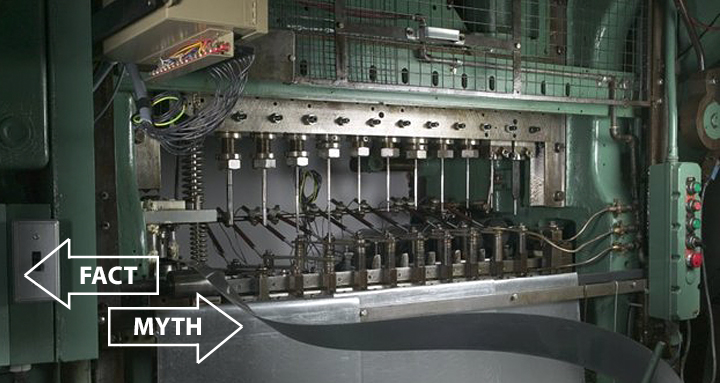

The deep drawn metal stamping process holds a clear advantage over other types of metal forming in several key ways.

When someone talks about the deep drawn process and the products that are created by it, the topic seldom turns

Keep it simple. These are buzz words for any good engineer or inventor to follow. Legends surrounding the creation of

When you finally find the time to sit down and take a close look at the products and processes your

In 1965, the first anti-gravity space pen™ was patented. These pens were unique in their ability to write in a

Metal stamping processes are one of the most common methods used to shape sheet metal of many different materials into

Choosing the right supplier for Deep Drawn Metal Stamping is very important when you want the best results. Listed here

Deep Drawn Metal Stamping competes with many other types of manufacturing processes that create the same or similar products. The

With all of the technology available in the manufacturing industry today, it can be daunting to decide which method would

Accurate Forming was established in 1955 and is recognized as a leader in the art and science of Deep-Draw Metal

Accurate Forming is a Deep Draw Metal Stamper who was established in 1955. All of Accurate Forming’s operations take place

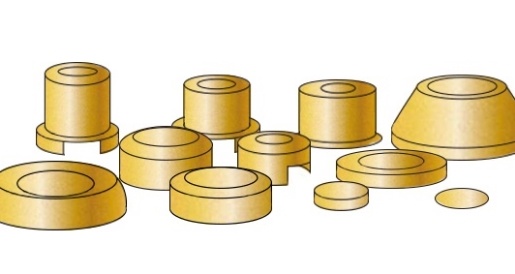

Deep drawn metal stampings can be classified into 3 categories, simple, average & difficult. Simple drawn parts usually have the

Let’s look at the different stations that we can have in the press and their functions. As mentioned previously, the

The blank for the part to be drawn is removed from the strip and moved into the transfer slide. The

When a part is being designed for the deep draw process considerations must be given to the following:

Accurate Forming is a Deep Draw Metal Stamper who was established in 1955. All of Accurate Forming’s operations take place

Accurate Forming utilizes different raw materials based on the customer and part needs. They are as follows:

During the deep draw stamping process, once the blank for the part to be drawn is removed from the strip

When a part is being designed for the deep draw process considerations must be given to the following:

Accurate Forming produces deep drawn stampings from deep drawing stainless steel alloys, deep drawing copper alloys, and deep drawing steel,

Accurate Forming produces Automotive Components from deep drawing stainless steel alloys, deep drawing copper alloys and deep drawing steel, low

Accurate Forming produces components for Medical Instruments from deep drawing aluminum, deep drawing copper alloys, deep drawing stainless steel, deep

Accurate Forming produces Ordnance components from deep drawing aluminum, deep drawing brass, as well as copper, stainless steel, and cold

Accurate Forming produces Marker Pen Components from deep drawing aluminum. These deep drawn components are used in both commercial and

Accurate Forming was established in 1955 and is recognized as a leader in the art and science of deep-draw metal

Providing You a Turnkey Product Saves you Time and Money!

For this week’s posting we have below examples of some of the things we have discussed regarding our secondary operations

Accurate Forming offers several Value Added Secondary Operations to our customers. This week we continue with more of those operations;

Accurate Forming offers several Value Added Secondary Operations to our customers. This week we continue with more of those operations;

Accurate Forming offers several Value Added Secondary Operations to our customers. The following are some of those operations:

Accurate Forming’s engineering department becomes involved early on in the sales process and stays involved through the manufacturing process until

There are a number of different raw materials that are suitable for the deep draw process. Today we will examine

There are a number of different raw materials that are suitable for the deep draw process. Today we will examine

There are a number of different raw materials that are suitable for the deep draw process. Today we will examine

There are a number of different raw materials that are suitable for the deep draw process. Today we will examine

When a part is being designed for the deep draw process considerations must be given to the following:

Tip 1: Embedding Video into Your Blog

Accurate Forming’s customer service team distinguishes itself from other deep draw houses. In complex projects, Accurate Forming is capable of

With the customer being the number one priority, Accurate Forming prides itself in our relationships with our customers. Accurate Forming’s

What makes Accurate Forming unique is our ability to produce extremely high quality deep drawparts with long lengths, small diameters and very tight

Continuing from last week we will take a look at Accurate Forming’s Quality capabilities. Accurate Forming recognizes the Customer as

Accurate Forming is proud of the extremely tight tolerances that we hold on the full range of deep drawn parts we produce.

Moving forward with our examination of part characteristics, the next type of part would be classified as difficult. These parts

Deep drawn metal stampings can be classified into 3 categories, simple, average & difficult. Simple drawn parts usually have the

Deep drawn metal stampings have basic dimensional characteristics. The first of these would be in regard to material thickness. The

As we continue forward in understanding the deep draw process, let’s look at the different stations that we can have

Continuing from last week’s post, the blank for the part to be drawn is removed from the strip and moved

When a part is being designed for the deep draw process considerations must be given to the following:

Get a Custom Quote Today!

Looking for precision metalworking services tailored to your specific needs? Let’s bring your vision to life! Contact us to receive a personalized quote. Our team is ready to provide you with expert advice and a detailed estimate for your project. Simply fill out our quick form, and we’ll get back to you with a competitive quote that matches your requirements.